Electricity demand in Sub-Saharan Africa is expected to more than triple by 2040, posing a great threat of deforestation and pollution.

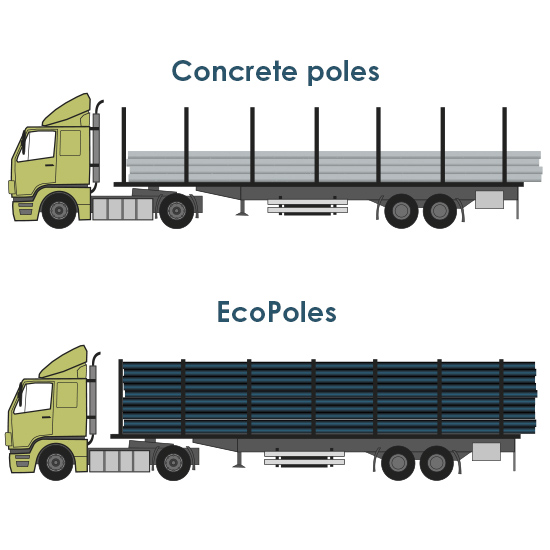

Building energy grids for distribution of electricity to rural areas is demanding. The investments are high, and the carbon footprint can be of considerable harm to the environment.

Millions of trees every year

Today, mainly wooden poles are used for building the necessary electrical grids. Every year millions of trees are used for this purpose, contributing to deforestation and desertification as the end result. Desertification is the process by which fertile land is transformed into desert.