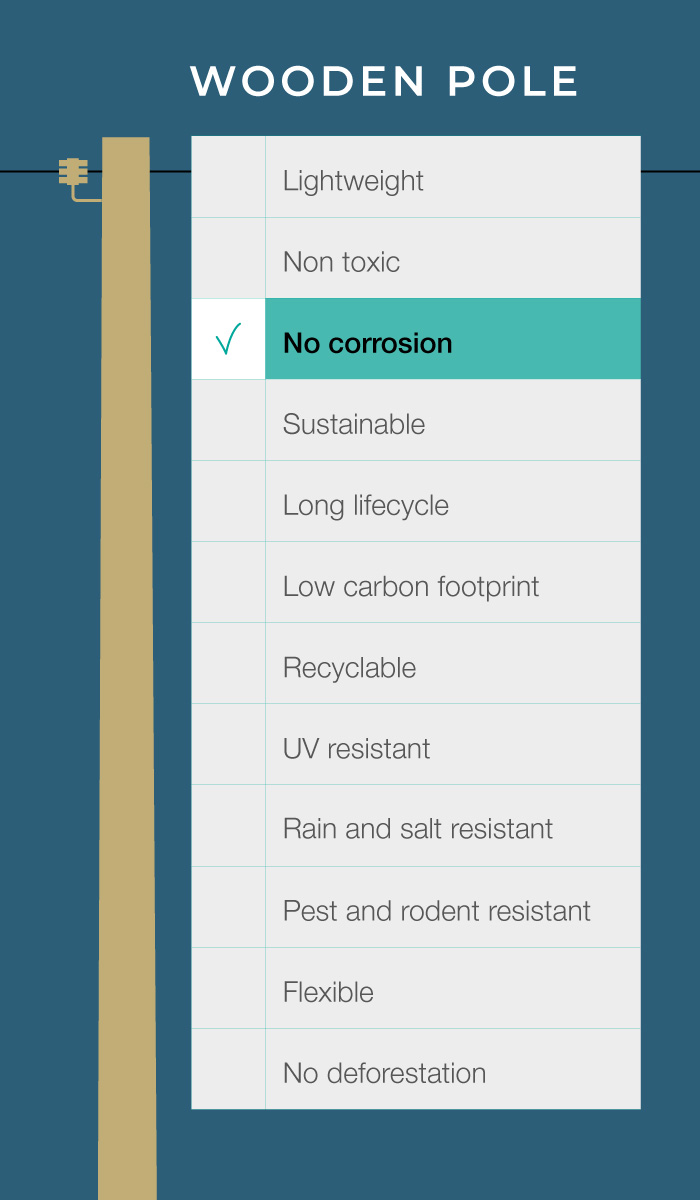

In addition to reducing deforestation and pollution of ground water and top soil, there are several advantages that puts EcoPole in front as the superior alternative for the distribution of electricity to rural areas.

The advantages of EcoPole

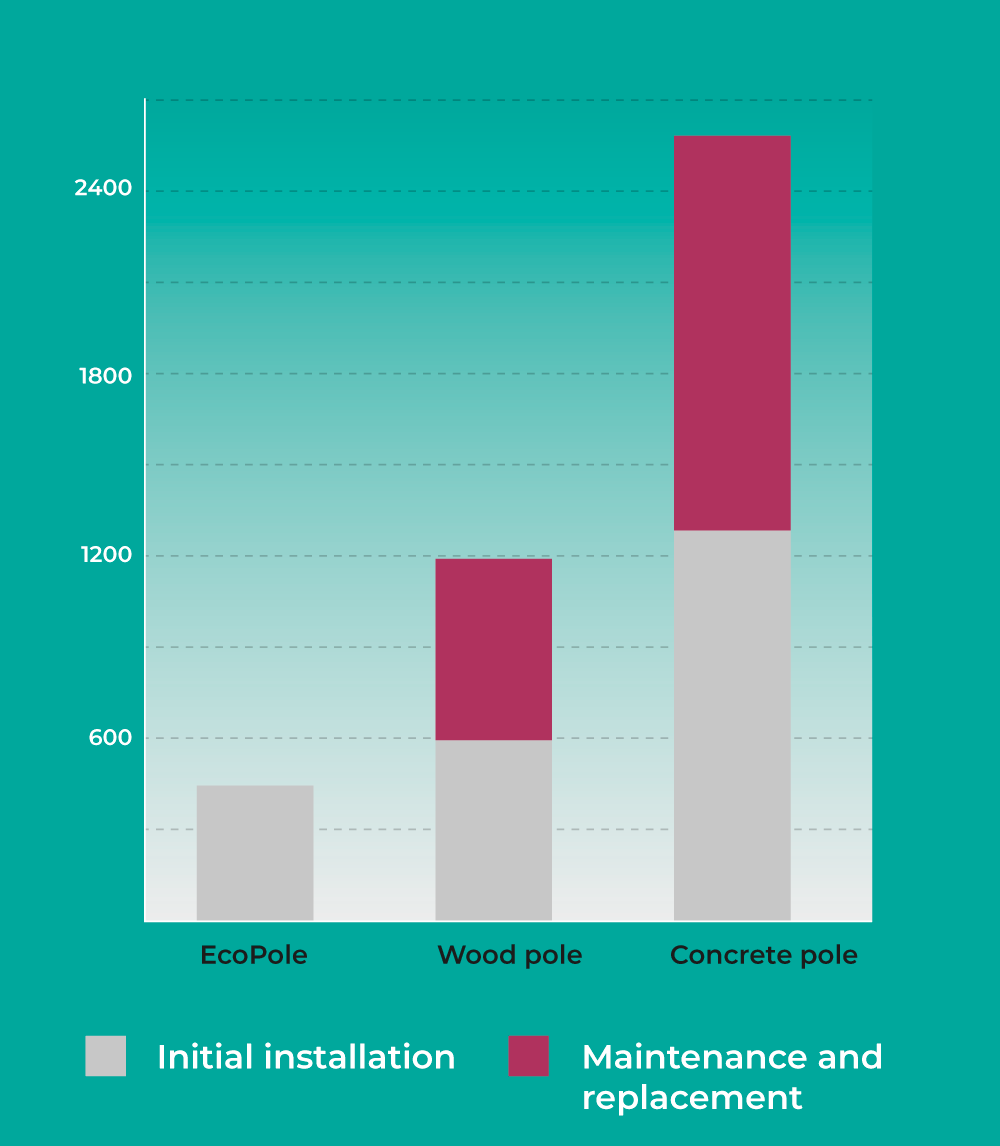

As a consequence of its durability, lightweight and long lifecycle, EcoPole is the most cost-efficient choice for distribution of electricity.

Lightweight

Easy to transport and handle

All materials used in the EcoPole are lightweight, making the pole up to 50% lighter than wooden poles and up to 80% lighter than concrete poles. As a consequence, handling is easier and areas with poor infrastructure can be reached.

The poles can be handled by manual labour, both loading, unloading and mounting the pole into place. Cranes can be avoided and smaller vehicles and boats can be used to reach rural areas. The light weight also makes regular transport more cost-efficient, as more poles can be loaded on each truck.

Easy to install

The light weight means that the pole can be installed by manual labour, and there is no need for concrete foundation or other means of support in regular soil. After an installation hole is dug out according to the width and depth specifications, the pole is simply lifted in and stabilized by the use of ropes and manpower.

The possibility of avoiding cranes and lifting equipment is one of the advantages that makes EcoPole a better choice for energy distribution to rural areas.

Same equipment as for wooden poles

No special tools are required for EcoPoles. The poles can be arranged for conventional installation of power transformers, and it uses the same bolts, fittings and climbing equipment as wooden poles. The HDPE outer material and standardized size makes climbing predictable and safe.

LIGHTWEIGHT

Durable

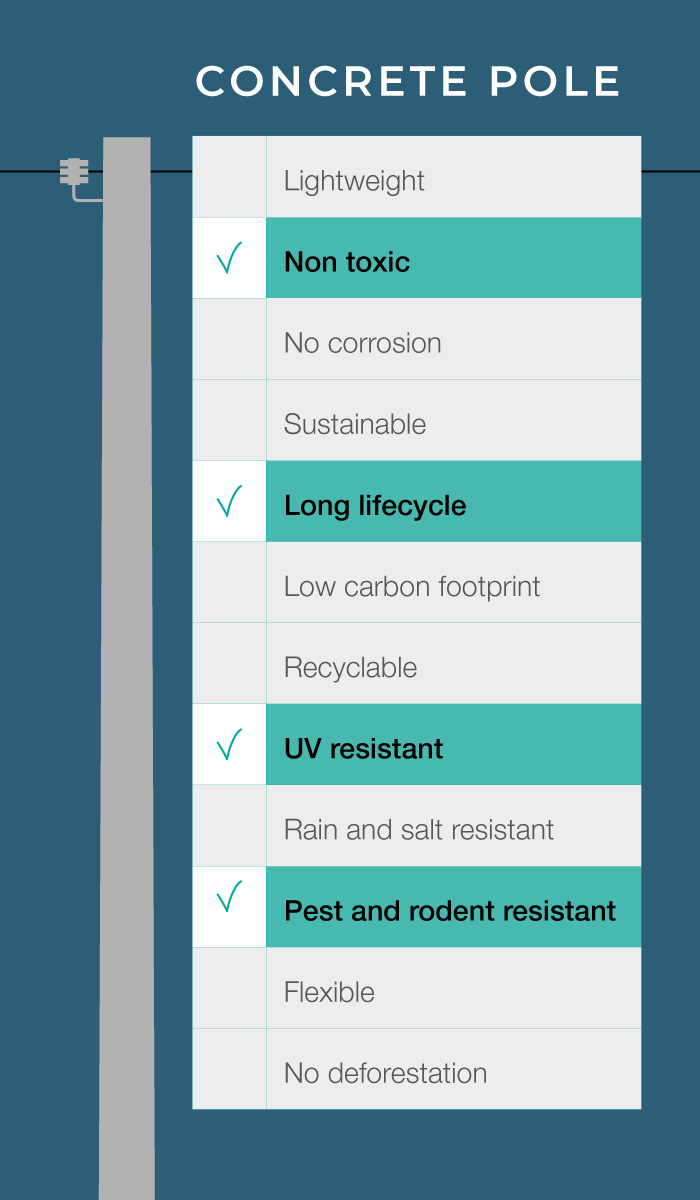

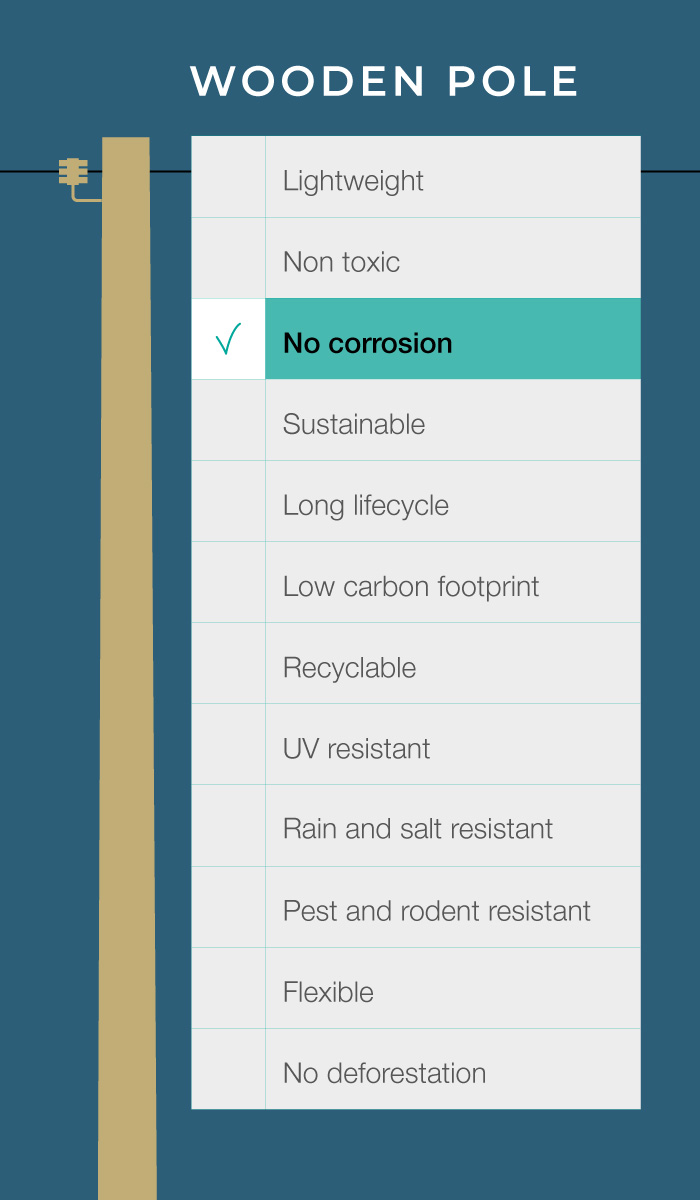

The construction of the EcoPole is specifically designed to make it durable under all conditions. Corrosion, termites, rodents, woodpeckers and UV radiation are the main challenges that make wooden and concrete poles deteriorate over time.

The protective HDPE pipe and the binding material polyurethane foam, are the key differentiators compared to concrete and wooden poles.

HDPE is a fully recyclable plastic that protects the pole from all these potential damages. The material is tested for a variety of insects and sun exposure over time, without any signs of deterioration. HDPE withstands rough handling, but should the outer layer be damaged by an unexpected incident, the foam inside is also resistant to termites, and the pole will still be intact for a long period of time.

There is no need for maintenance, and the long lifecycle extends the investment period dramatically by the use of EcoPoles. The expected life cycle of an EcoPole is normally more than 50 years, and we grant a commercial warranty of 20 years.

3 m drop test

EcoPole meets the requirements of Kenya Bureau of Standards (KS 2513: 2014), passing a drop test of three meters without any damage.

UV RESISTANT

NO CORROSION

TERMITE AND RODENT RESISTANT

3 m drop test

EcoPole meets the requirements of Kenya Bureau of Standards (KS 2513: 2014), passing a drop test of three meters without any damage.

UV RESISTANT

NO CORROSION

TERMITE AND RODENT RESISTANT

Flexible

The unique material composition makes the poles both strong and flexible. This allows them to withstand high wind loads and vibrations.

The strong bamboo fibres are held in place by a semi-rigid polyurethane foam, forming a unique combination. Unlike concrete and wooden poles, the composite pole will not experience sudden fractures at high loads. Instead, the pole will gradually bend and not break and cause no harm to the surroundings.

EcoPole has a controlled deformation at high loads and will not break. Extensive load tests even show that the pole will straighten itself shortly after removing unwanted stress.

FLEXIBLE

Cost-effective

With its light weight, durability and flexibility, EcoPole is very cost-efficient due to long lifecycle.

During its lifecycle, considering price, installation and transport cost, EcoPole is a better investment than both wood and concrete poles.

Cost estimate 20 year life cycle in % (pole, installation and transport)